POLYURETHANE O RINGS

POLYURETHANE O RINGS Specification

- Manufacturing Process

- Injection Moulded / Cast

- Shape

- O Ring

- Hardness

- 70 to 95 Shore A

- Storage Recommendation

- Store in a cool, dry place away from direct sunlight

- Size

- Customizable / As per requirement

- Tensile Strength

- Minimum 40 MPa

- Water Absorption

- Negligible

- Compression Set

- Low (as per DIN standards)

- Lifespan

- Long operational durability under recommended conditions

- Oil Resistance

- Good

- Material

- Polyurethane

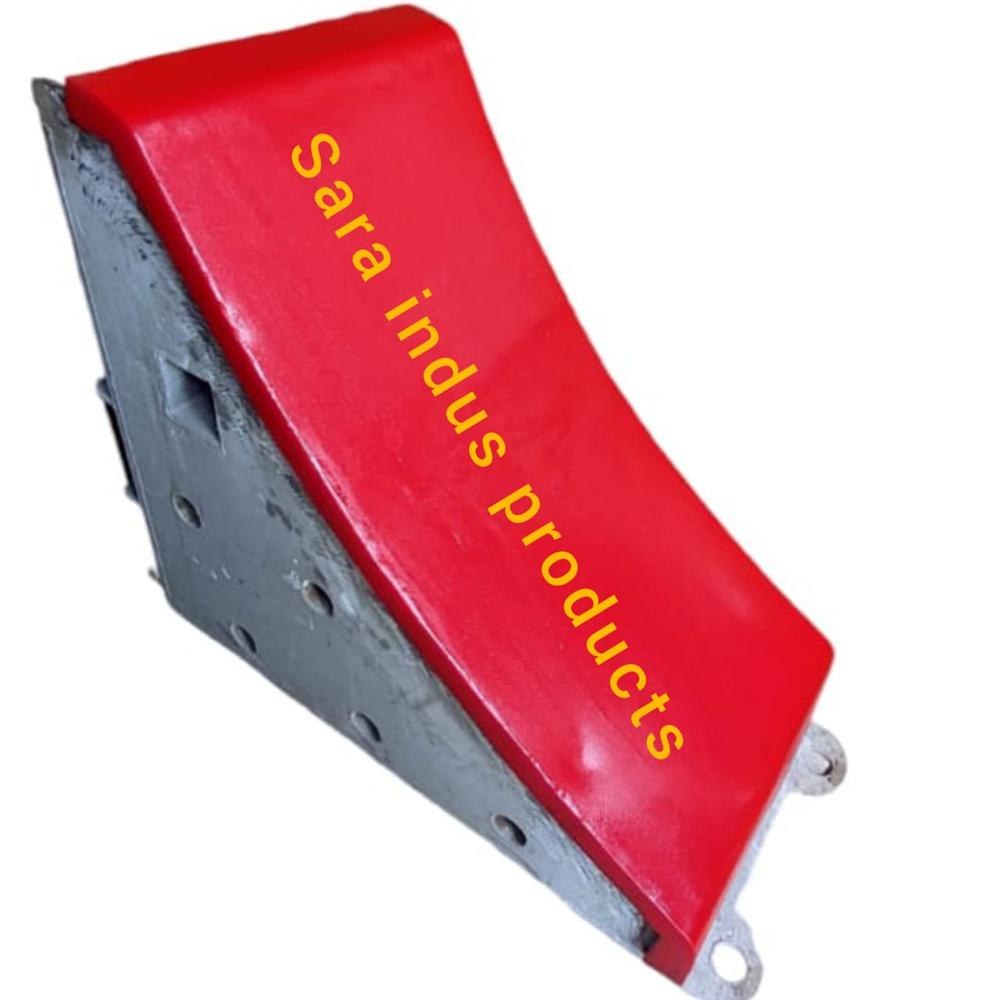

- Color

- Red

- Application

- Hydraulic cylinders, pneumatic systems, sealing applications

- Temperature Range

- -30°C to +80°C

- Abrasion Resistance

- Excellent

- Elongation at Break

- 400% to 700%

POLYURETHANE O RINGS Trade Information

- Minimum Order Quantity

- 5 Number

- Delivery Time

- 7 Days

About POLYURETHANE O RINGS

Polyurethane O-rings are sealing components made from polyurethane, a highly durable and flexible

polymer. O-rings are circular seals that are used to prevent leakage of fluids or gases between two

mating surfaces, typically in dynamic or static applications. Polyurethane is chosen for O-rings due

to its superior mechanical properties, which include high abrasion resistance, excellent chemical

resistance, and long-term durability.

APPLICATIONS :

Aerospace

Oil and Gas

Automotive Industry

High-Performance Sealing Solution

Polyurethane O Rings stand out for their exceptional load-bearing capacity, abrasion resistance, and reliable sealing in demanding environments. With excellent oil resistance and a low compression set, these O rings outperform conventional elastomers, ensuring extended service life and integrity, especially in hydraulic and pneumatic applications. Their superior physical properties make them suitable for a range of industrial uses.

Custom Manufacturing for Diverse Applications

Our O rings are injection moulded or cast to meet exacting client specifications, ensuring a precise fit every time. With customizable sizes and hardness (70 to 95 Shore A), we accommodate varied requirements, from small pneumatic fittings to large hydraulic cylinders. Their versatility and adaptability make them trusted components across multiple industries.

Proper Storage and Longevity

To maximize lifespan, Polyurethane O Rings should be stored in a cool, dry environment, shielded from direct sunlight. Following these guidelines ensures long operational durability and preserves material properties, guaranteeing optimal performance whenever they are put into use.

FAQ's of POLYURETHANE O RINGS:

Q: How are Polyurethane O Rings manufactured and why does the process matter?

A: Polyurethane O Rings are typically produced through injection moulding or casting, ensuring consistent quality and precision in dimensions. This process guarantees that each O ring meets strict standards for tensile strength, abrasion resistance, and sealing performance, making them reliable for industrial applications.Q: What applications benefit most from these O Rings?

A: These O Rings are particularly advantageous in hydraulic cylinders, pneumatic systems, and other sealing applications requiring durability, oil resistance, and excellent abrasion protection. Their performance attributes make them ideal in both dynamic and static sealing environments across various industries.Q: When should I choose polyurethane O rings over other materials?

A: Polyurethane O Rings are preferred when high tensile strength, excellent abrasion resistance, and low compression set are critical-in environments exposed to oils, mechanical stress, or where longevity is important. They outperform many traditional elastomers in industrial and automotive applications.Q: Where can these O Rings be sourced in India?

A: You can obtain Polyurethane O Rings from dealers, distributors, exporters, importers, manufacturers, producers, retailers, service providers, suppliers, and traders throughout India, ensuring convenient access for all users.Q: What storage conditions are recommended for Polyurethane O Rings?

A: Store the O Rings in a cool, dry place away from direct sunlight. Adhering to these storage guidelines helps preserve their mechanical properties, ensuring long operational life and reliable sealing performance.Q: How does the negligible water absorption of these O Rings benefit industrial applications?

A: Negligible water absorption guarantees that the O Rings do not swell or degrade in moist environments, preserving their sealing integrity and mechanical strength even in humid or wet conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free